Overview

In oil or gas extraction processes, optimizing production methods is crucial. It is particularly important to accurately understand the flow rates, volumes, flow patterns, and cumulative trends of solid particles during extraction. The sand monitor developed by Lightwaves measures the flow rates, instantaneous flow, and cumulative flow of solid particles during crude oil extraction, natural gas extraction, gas storage injection and production, drilling, logging, fracturing, well completion, workover, and cementing processes.

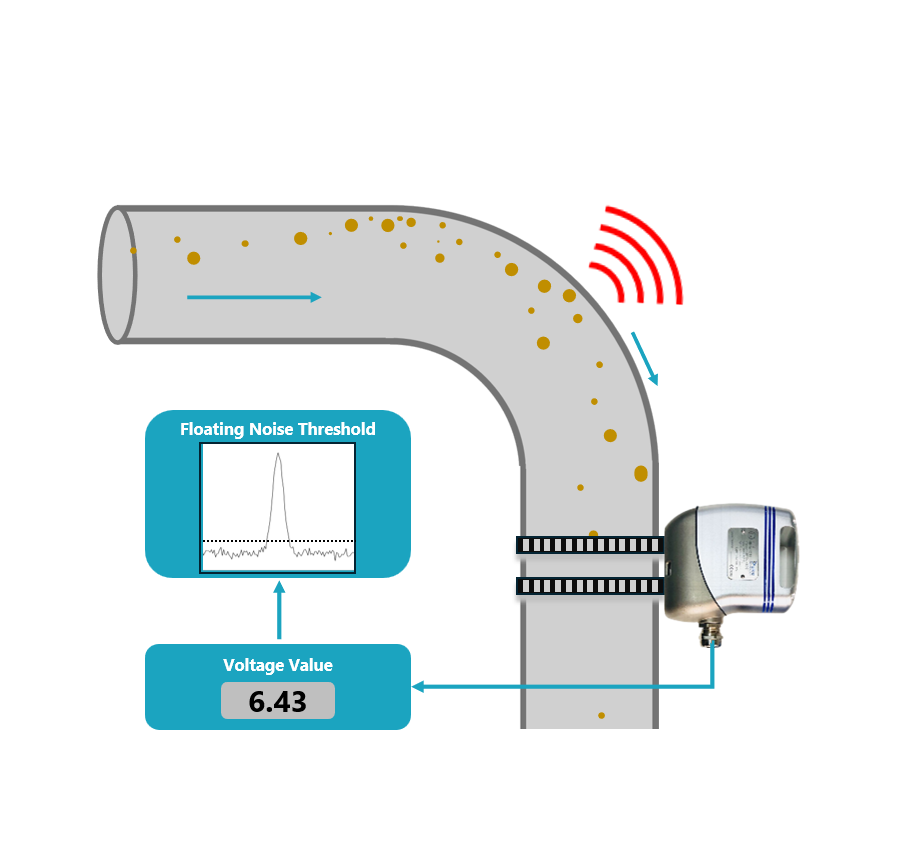

The sand monitor consists of two parts: a compact and robust clamp-on acoustic sensor and a sand and gravel transmitter. It can be applied in any oil & gas field where efficient extraction is needed, allowing for real-time, accurate, and quantitative measurements of sand and gravel flow.

In recent years, there has been a market demand for real-time measurement of particle capacity and flow rates. The unique sensor is installed at appropriate pipeline connections or bends, where the turbulent profile is most representative of fluid characteristics. The sensor directly integrates measurements of solid particle content and flow, eliminating the need for additional flow rate measurements.

Features

l

Optimizes production efficiency

l Suitable for multi-phase fluids

l Qualitative and quantitative measurement

l Pipeline & valve hazard assessment

l Non-Contact, easy to Install, easy to calibrate

l Facilitates most efficient control methods

l Measures sand flow in oil and gas wells

Principle

In oil or gas extraction wells, solid particles/sand gradually increase with the extraction process. As the well ages, solid particles/sand adhering to the inner walls of the well or pipeline will accumulate year by year, potentially leading to blockages. It is essential not only to prevent the increase of solid particles/sand but also to optimize the production process, which presents a significant technical challenge. If not managed properly, these particles/sand can cause damage to pipelines or valves. Therefore, it is crucial to monitor the flow rate, instantaneous flow, cumulative flow, and movement patterns of sand in the pipeline in real time.

The unique acoustic sensor is an intrinsically safe unit (ATEX EEx ia IIC T4), made from 316 stainless steel, with a protection rating of up to IP68. The installation is very simple. The sensor can be bundled and installed on the outer wall of the pipe with a stainless steel band, or connected to the pipe turning joint through a stainless steel adapter, thereby receiving the sound waves generated by the collision of solid particles with the pipe wall inside the pipe. Since the sensor only receives signals from a very narrow bandwidth, it effectively filters out noises generated by gases or liquids. Changes in the frequency and amplitude of the acoustic signals can reveal the flow rate, instantaneous flow, cumulative flow, and movement patterns of sand in the pipe.

Types

Functions

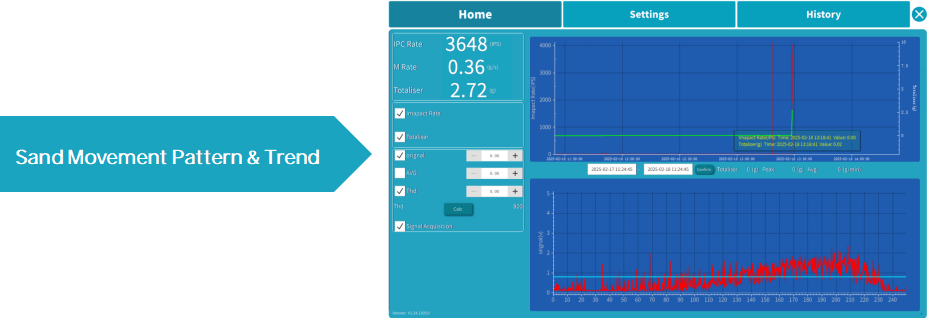

The LT 901 Series Sand Monitor integrates the measurement of fluid patterns, flow rate, instantaneous flow, and cumulative flow of sand. It is a low-cost, real-time monitoring system for predicting the flow patterns and cumulative trends of sand. All data is transmitted through the compact main unit of the sand monitoring system (which includes a Zener barrier and RS485 (Modbus) data and communication module), allowing for data transmission over distances of up to 1500 m. It can connect to the customer's data acquisition systems, such as DCS, PLC, and SCADA systems, to monitor the flow rate, instantaneous flow, and cumulative flow of sand in crude oil & gas pipes. The data can also be stored in the main control unit or imported and downloaded to a PC for analysis via cable connections.

Technical Parameters

LT 901 Controller - Compact | ||||

Power: | 110/240V AC@50/60Hz 24V DC 10W | Software: | Linux-based data processing software | |

Accuracy: | 0.01g/s (optional 0.001g/s) | |||

Temperature: | -40℃~+70℃ | Docking: | M20 Aviation Connector, 1/2"NPT | |

Output: | RS485 (Modbus), 4~20mA analog signal, optional RS232, 2 alarm relay outputs | |||

Protection: | IP56, IP66, IP68(optional) | Transmission Distance: | 1200 m | |

Weight: | 15.5Kg | Size: | 300x300x170mm | |

Enclosure: | 316L Stainless Steel | EPC: | Exd IIB T4 EEx ia IIC T6, EEx ia IIC T4 | |

LT 901 Controller - Fixed | ||||

Power: | 110/240V AC@50/60Hz 24VDC 15W | Software: | Linux-based data processing software | |

Accuracy: | 0.01g/s (optional 0.001g/s) | Storage: | 91Days, 25Years (32GB storage card) | |

Temperature: | -40℃~+70℃ | Docking: | M20 Aviation Connector, 1/2"NPT | |

EPC: | ATEX Ex ia IIC T6, Ex ia IIC T4, Ex db ia IIB T4, Ex db ib IIB T4 | HMI: | 7" LCD Touch Screen | |

Output: | Analog 4-20mA/0-20mA @ 500 ohms (Tunable) 0.1% accuracy | |||

Wall-Mount: | Size:400 x300 x200mm; Material: 316L stainless steel; Protection: IP56, IP66, IP68; Weight: 20kg | |||

Desk-Mount: | Size: L300 xH200 xW300mm; Optional Protection: IP65, IP66, IP68; Weight: 18kg | |||

Rack-Mount: | Size: 3UX84HPW(H133 x 482 x300mm); Weight: 20kg | |||

LT 901 Controllerr - Portable | ||||

Power: | Lithium Battery, Runtime > 24 Hours | Temperature: | -40℃~+70℃ | |

Accuracy: | 0.01g/s (optional 0.001g/s) | Storage: | 25 years (32GB storage card) | |

EPC: | ATEX Ex ia IIC T6, Ex ia IIC T4, Ex ia IIB T4, Ex db ib IIB T4 | |||

Output: | Digital, RS485 Modbus, Ethernet | HMI: | 7" LCD Touch Screen | |

Protection: | IP65 (case closed), IP50 (case opened); Size: L410xW300 xH190mm; Weight: 10kg | |||

Processing and Analysis Software --- LDsandview | ||||

Linux-based data processing software; It has functions such as recording, storage, analysis, history, trend analysis, and report printing, and the parameters of the controller host can also be configured. | ||||

LT 901–W Controller - Wireless | ||||

Power: | Lithium Battery, runtime > 48 hours | Temperature: | -40℃~+70℃ | |

Accuracy: | 0.01g/s (optional 0.001g/s) | Storage: | 25 years (32GB storage card) | |

EPC: | ATEX Ex ia IIC T6, Ex ia IIC T4, Ex ia IIB T4, Ex db ib IIB T4 | |||

Output: | Communication methods: WiFi, Bluetooth, 4G, LORA, Zigbee, etc. Communication protocol: Modbus485, network port, etc. | |||

Protection: | IP56, IP66, IP68 (optional) | Size: | L400 xW350 xH230mm | |

Applications

l Oil/gas field production and exploitation

l Analysis of Production Trends

l Fracturing operation monitoring

l Well workover and completion operation

l Gas storage monitoring

l Pipeline erosion warning

l Efficiency evaluation of the pig detector

l Evaluation of hydrate inhibitors

Copyright © Lightwaves Website Map