Overview

The Lightwaves LT 904 Pipe Thickness Monitor provides real-time monitoring solutions for corrosion/erosion in pipelines. It integrates mature ultrasonic pipe thickness monitoring sensors, advanced real-time data transmission hardware, and data visualization suite, delivering highly accurate and repeatable measurements of pipe thickness, metal loss, and corrosion/erosion monitoring. This system is an important tool for studying metal corrosion/erosion rates and mechanisms, providing reliable data for the selection of corrosion/erosion prevention processes.

Features

l Safe, convenient and reliable

l Real-time monitoring & high cost performance

l Global remote visualization, with an optional local secure cloud

l High-repeatability and high-accuracy data and trend analysis

l Non-invasive, ideally choice for applications in high temperature, high pressure and acidic environments

l Directly measure the absolute wall thickness to identify corrosion/erosion activities early

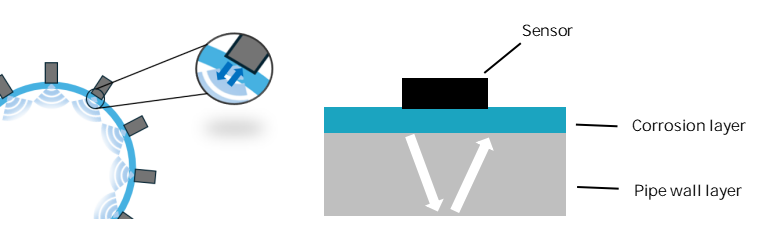

Diagram of 3D acoustic thickness

Principle

Based on echo sensing technology, the LT 904 Pipe Thickness Monitor uses high-frequency sound waves generated by piezoelectric transducers to pass through materials. It measures the time for echoes to return to the sensor or records the amplitude of sound waves when resonance occurs as signals to detect defects or measure absolute pipe thickness. It can identify corrosion/erosion activities at an early stage, allowing for continuous monitoring in high-risk areas and providing accurate and repeatable results.

Principle of Pipe Thickness Monitor

Technical Parameters

LT 904 Pipe Thickness Monitor | |

Output Data: | Pipe thickness, corrosion/erosion rate, metal loss rate, temperature, raw signals, etc. |

Pipe Size: | Diameter ≥ 80 mm |

Thickness: | 3 mm to 500 mm |

Repeatability: | < 2.5 μm |

Pipe Material: | Steel or solid homogeneous materials |

Coating Material: | Can penetrate external uniform PE/PP/FBE coatings |

Sensor: | Pulse/echo, 10 mm diameter, 5~25 MHz sampling frequency |

Power Consumption: | < 1 W (active), < 0.1 W (idle) |

Number of Sensors: | Flexibly configurable |

Installation Method: | Non-intrusive clamping installation on the outer wall of the pipe |

Temp Range: | -40℃~+125℃, ±0.1℃ |

Thickness Loss Rate Resolution: | When the pipe wall thickness is 10mm and the temperature difference is within ±1℃, data is collected once a day. For a corrosion rate of 0.04mm/year, monitoring time is 30 days; for a corrosion rate of 0.002mm/year, monitoring time is 1 year, with a data reliability of 95%. |

Explosion Proof: | Ex ib lIB T4 Gb |

Protection Rating: | IP66, IP67, IP68 (optional) |

Software: | Based on Windows operating system, debuggable and operable DKPipeDia monitoring station; provides corrosion rate, thickness, temperature data, historical trends, and raw signals. |

PC Requirements: | Core i5 processor, 8GB RAM, 512GB storage hard drive |

Server Output: | Modbus RTU, Modbus TCP, web-based interface (optional) |

Portable Data Logger: | Operates and powers the monitoring station via Wi-Fi, Bluetooth, or communicates with fixed data recorders via Bluetooth or USB |

Operating System: | Windows, with full DKPipeDia software |

Cable Box: | Protection rating IP65, stainless steel material for field cable box |

Fixed Data Recorder: | Self-operating monitoring station installed in a stainless steel enclosure with protection rating IP65 |

Power Supply: | 9~36V DC, 110~24 V AC, battery |

Power Consumption: | < 6 W |

Communication: | Wi-Fi, LoRa, 4G, Ethernet, Modbus TCP/IP, OPC (optional) |

Pipe Operating Temperature: | -40℃~ +125℃ |

Ambient Temperature: | -40℃~ +60℃ |

Operating Modes: | Manual, semi-automatic, fully automatic (configurable) |

Applications

l High corrosive medium pipeline

l Reactor outlet pipeline

l Catalyst conveying pipeline

l Boiler feed water/steam pipeline

Copyright © Lightwaves Website Map