Overview

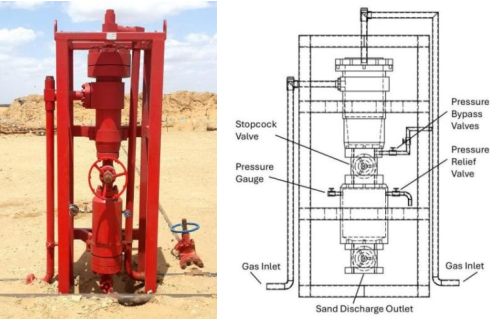

The LT 903 Gas-Solid Separator is widely used in on-shore condensate gas fields at natural gas wellheads and pilot testing sites, as well as in off-shore condensate gas platform wellheads. The primary purpose of this separator is to remove coarse sand particles from the natural gas produced by gas wells through a swirling motion, thereby protect subsequent processing equipment from damage. The key components of the LT 903 Gas-Solid Separator include a swirl barrel, a sand settling tank, and supporting process valves. It is also equipped with a safety venting device to ensure safe operation.

Features

l Flexible, diversified and customizable;

l Small size with high processing capacity, saving the space.

l The sand settling tank is designed for ultra-high pressure to ensure safe operation.

l Easy to operate and transport, reliable and safe.

l Capable of accommodating 10%~150% fluctuations in natural gas production.

l Can work uninterrupted during operation and avoid shut-in and sand removal.

l Prevents secondary contamination of oil quality associated with other sand removal methods.

Principle

The LT 903 Gas-Solid Separator operates on the principles of centrifugal sedimentation and density differences. When the fluid enters the separator tangentially at a certain pressure, it generates intense rotational motion. Due to the differences in fluid density, the forces of centrifugal force, centripetal buoyancy, and fluid drag act differently on the components. This results in the lower-density gas rising and being discharged through the separator outlet, while the higher-density sand is expelled from the sand discharge outlet at the bottom of the device, achieving the goal of sand removal.

Installation

The Gas-Solid Separator should be installed on the main pipeline of the gas supply network and secured to a base. A bypass should be added between the separator outlet and the sand settling tank. When installing the Gas-Solid Separator, ensure there is sufficient maintenance space around it. During normal operation, the plug valve between the swirl barrel and the sand settling tank must be opened, while the sand discharge valve and bypass valve should be closed.

![]()

![]()

Technical Parameters

LT 903 Gas-Solid Separator | |||

Natural Gas Processing Range: | > 1200 m³/h | Solid Removal Rate: | 99% |

Working Temperature: | -20℃~+100℃ | Environment: | Acid -resistant; sulfur-resistant |

Designed Pressure: | 42 MPa | Working Pressure: | < 30 MPa |

Container Weight: | 8000 kg | Volume: | 3.7 m³ |

Container Shell Material: | Q245R | ||

Dimensions: | 1000mm x 1000mm x 3600mm | ||

Appearance Indicators: | Sandblasted and polished, inorganic zinc primer, epoxy resin intermediate coating, acrylic polyurethane outer coating. | ||

Processing Capacity: | Gas phase: over 1.2 million m³ per day at maximum pressure | ||

Liquid phase: 800 m³ per day with a 2-minute delay time. | |||

*Customization available according to user requirements *

Applications

l Oil and gas extraction

l Oilfield drilling

l Coalbed methane drilling mud purification

l River water and well water sand removal

l Industrial mineral processing

l Solid-liquid separation

l Liquid degassing

l Separation of non-miscible liquids

Copyright © Lightwaves Website Map