Overview

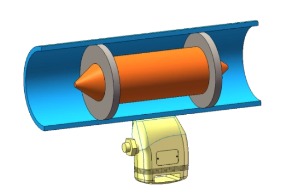

Pipe cleaning is a part of the daily operations of many sea and land facilities. The operator needs a reliable method to confirm whether the pig has left the pig launcher or arrived at the receiving end. The LT 902 series pipeline pig detector is based on our patented acoustic intelligent sensor technology platform, with a compact structure and easy to use. The speed and simplicity of its installation principle are unmatched by other ball indicators. In addition, it can accurately and reliably detect all types of cleaning devices without the need for any inserts.

Features

l Optimizes production efficiency

l Real time measurement

l Non-intrusive, easy to install

l Refit/install without shutdown

l Support local or remote indication

![]()

Principle

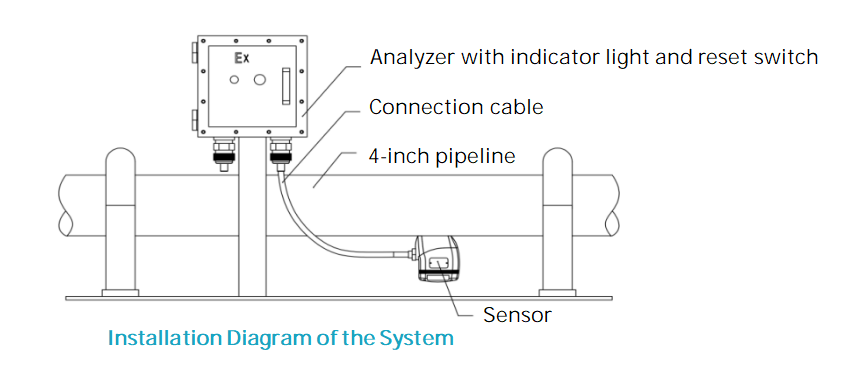

The LT 902 Series Pipeline Pig Detector utilizes passive acoustic technology to sense the pig passing through the pipeline and is equipped with a frequency locked digital signal processor (LPDSP). When the pig passes the positioning point of the detector, the instrument will detect and analyze the signal level changes at multiple frequencies. The indication of the pig passing can be displayed by the local light on the instrument, or by the signal output to the control system or indicator panel. The signal output is either "Pig Pass" or raw ball pass data used for further analysis. By using a computer equipped with Lightwaves's proprietary software or by inputting data into the main control system, users can obtain graphical displays of the signals received from the pig detector. The output is 4~20mA analog or RS485 digital signal.

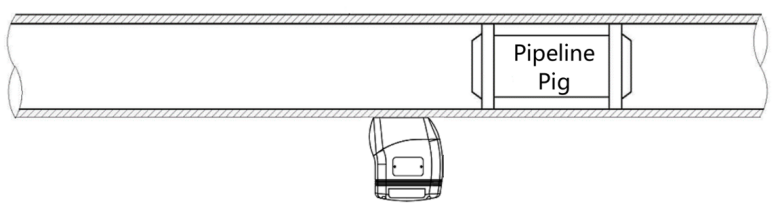

Diagram of Pig and Sensor Positions

Technical Parameters

Sensor | |||

Principle: | Intelligent Acoustic Sensor | Installation: | Clamp-on (Non-intrusive) |

Protection: | IP56, IP65, IP66, IP68 (Optional) | Ambient Temperature: | -40℃ to 60℃ [-40℉ to 140℉] |

Accuracy: | ±2s | Pipeline Temperature: | -40℃ to 150℃ [-40℉ to 300℉] |

Power: | 24VDC@2.8W, 110/240VAC 50/60Hz, Solar, Lithium Battery (Optional) | Docking: | M20 Aviation Connector, 1/2" NPT |

Output: | 2 Alarm Relays, 4-20 mA/0-20 mA Analog, RS-232, RS-485 (Modbus RTU, Profibus Protocol) | ||

Alarm Indication: | Relay, Local Light, External Light, MCS, 4-20 mA, via RS485 connection to Modbus | ||

Material: | 316 Stainless Steel | Weight: | Ex ia<3kg, Ex de/m <8kg |

Software: | Windows-based Analysis Testing Software, Embedded (Optional) | EPC: | Ex db ia [ia IIC Ga] IIB T6 Gb |

LT 902 Controller - Fixed | |||

Power: | 110/240VAC@50/60Hz、24VDC@15W | Software: | Linux based, embedded |

Temperature: | -40℃~+70℃ | Docking: | M20 Aviation Connector, 1/2" NPT |

EPC: | EEx ia IIC T6, EExia IIC T4, ExdIIBT4 | ||

Output: | Analog 4-20mA/0-20mA @ 500 ohms (Tunable) 0.1% Accuracy | ||

Wall-Mount: | Size: 240x184x118mm Material: 316L Stainless Steel Protection: IP56, IP65, IP66, IP68 Weight: 10kg | ||

LT 902 Controller - Portable | |||

Power(Charging): Lithium Battery, Runtime > 24 Hours | Tamperature: | -40℃~+70℃ | |

Accuracy: | 0.01g/s (optional 0.001g/s) | Storage: | 25Years (32GB storage card) |

EPC: | ATEX EEx ia IIC T6, EEx ia IIC T4, EExia IIB T4, Exd IIBT4 | ||

Output: | Digital, RS485 Modbus, Ethernet | HMI: | 7" LCD Touch Screen |

Protection: | IP65 (case closed), IP50 (case opened) | Size: | 406x330x174mm |

LT 902 Controller - Wireless | |||

Power(Charging): | Lithium Battery, Runtime > 48 Hours | Tamperature: | -40℃~+70℃ |

EPC: | ATEX EEx ia IIC T6, EEx ia IIC T4, EEx ia IIB T4, ExdIIBT4 | ||

Output: | Digital, RS485 Modbus, Wireless;4G, 5G, LORA, ZigBee, Bluetooth, WiFi, optional | ||

Protection: | IP56, IP66, IP68 (optional); Size: 600x300x1500mm | ||

Applications

l Oil/gas transportation pipeline

l Chemical and process industry pipelines

l Maintenance of urban pipe networks

l Gas storage injection and production pipeline

l Pipeline hydro-static test

l Pipeline drying operation

l Leakage detection and location assistance

l Maintenance of industrial pipeline

Copyright © Lightwaves Website Map